When talking about contract filling, this is nothing more than contract filling. Wage bottling can be particularly interesting for companies that do not have their own bottling facilities. But there may also be other occasions and differences, as you can learn in the following article.

This is contract filling

What is contract filling? Who needs this process and why? Not so many people deal with contract filling. There are a large number of service providers in connection with filling. However, there are many differences depending on the service provider. For example, this starts with the product, what should be bottled. Depending on what product it is, you need an appropriate infrastructure for it. You can fill almost anything, from liquids to small-scale products or in powder form. Depending on what it is, what should be bottled, there are of course differences in terms of packaging. Whether can, glass containers, plastic containers, the materials that can be used here within the scope of packaging can be very different. Incidentally, this also applies to the size of the respective packaging.

Advantages of contract filling

For a company, of course, there is always the question of whether filling really pays off financially? Of course this is important. For example, what quantities it is, but also about the duration. The advantage of a contract bottling is just, you just have to deliver his product. The rest, namely the proper filling and packing takes over the respective service provider. Accordingly, you do not need to hold any machines, you do not need trained personnel and you do not need the necessary space for these work processes. Of course you have to meet these requirements if you want to fill yourself. Especially when it comes to test products in development or low-volume products, contract filling by caramba.eu will make more economic sense here. And so you can weigh the pros and cons accordingly.

What does contract filling cost?

Since there may be a number of differences in payroll, there are also differences in costs. For this reason, it is always advisable to obtain offers. So you get on the basis of concrete needs, be it in terms of packaging and quantity then a price. If you have several offers, you can see any price and performance differences between the offers. This way you can ultimately save money, because you can opt for the supposedly cheapest offer of contract filling in the end.

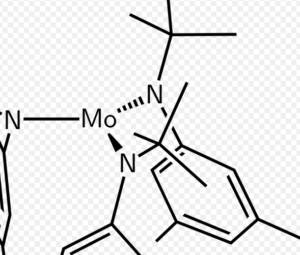

Tolyltriazole is mainly used in the chemical industry to protect copper from being contaminated in order to save the purity. Tolyltriazole also can be concernedly used with manifold sterilization algaecide and has a very fine corrosion mitigation effect on close cycle cooling water system. TTA also can be concernedly used with manifold sterilization algaecide and has a very fine corrosion mitigation effect on close cycle cooling water system. Tolyltriazole is a corrosion inhibitor for copper and copper alloys, and is commonly used in water cooling systems.

Tolyltriazole is mainly used in the chemical industry to protect copper from being contaminated in order to save the purity. Tolyltriazole also can be concernedly used with manifold sterilization algaecide and has a very fine corrosion mitigation effect on close cycle cooling water system. TTA also can be concernedly used with manifold sterilization algaecide and has a very fine corrosion mitigation effect on close cycle cooling water system. Tolyltriazole is a corrosion inhibitor for copper and copper alloys, and is commonly used in water cooling systems. Don’t forget about the comfort aspect when you are going to improve your home. Every house has something that needs to fixed up, but flaws that take away the comfort from your home can adversely affect your enjoyment while there. Comfort is often discounted as non-essential, but when you factor in quality of life, as well as aesthetics, the value becomes apparent. Try changing out stale lighting or increasing the number of people that you can seat in your living room. Little things can make a big difference. Add on to your home. Regardless of organization, some homes are just too small. Since relocating to a larger home is not practical for everyone, trying to add more space to your house will improve your quality of life. Even what may seem like a tiny bit of extra room can go a long way in eliminating the stress of clutter. Create more fun areas in your home. You can add something as simple as a home gym, and this will greatly increase the value of your home. Additionally, these enhancements can add value to a home.

Don’t forget about the comfort aspect when you are going to improve your home. Every house has something that needs to fixed up, but flaws that take away the comfort from your home can adversely affect your enjoyment while there. Comfort is often discounted as non-essential, but when you factor in quality of life, as well as aesthetics, the value becomes apparent. Try changing out stale lighting or increasing the number of people that you can seat in your living room. Little things can make a big difference. Add on to your home. Regardless of organization, some homes are just too small. Since relocating to a larger home is not practical for everyone, trying to add more space to your house will improve your quality of life. Even what may seem like a tiny bit of extra room can go a long way in eliminating the stress of clutter. Create more fun areas in your home. You can add something as simple as a home gym, and this will greatly increase the value of your home. Additionally, these enhancements can add value to a home.